Professional Chest Heated Ironers

- Attractive design

- Standard finger guard protection

- When unattended, the device shuts off automatically

- Reduced number of mechanical and moving parts for a lower maintenance cost

- Homogeneous ironing pressure to ensure top ironing quality

- PID controlled temperature regulation offering better temperature distribution and reduced energy consumption

- Long-life heating elements

- Anodised extruded aluminium profile avoiding temperature drop and ensuring top ironing quality

- All vital components are easily accessible

- Start/stop pedal

- Backside of the basin is insulated with 25mm ceramic wool - no energy waste

Professional Cylinder Heated Ironer

- Large surface contact with linen over an angle of 3000

- High polished steel, thin cylinder

- Finger protection and emergency button for more safety

- Durable Meta Aramid ironing belts

- Automatic cooldown

- Easy to operate microprocessor: 20 pre-set ironing programs

- Indication of ironing speed and temperature

- Reverse mode possible

- Frequency-controlled motor

- Easy to remove lint filters

- Space-savings installation against the wall is possible: front return

- Electric gas, or steam heating

- Overheating check system (OCS) with 3 temperature sensors

- Ergonomic design

Puffy-Pastry Machine Sheeter

This soldered steel machine is used for rolling dough to make Puff-Pastry, using two conveyor belts at different speeds. The rollers are made of chromium steel with upper and lower scrapers which can be easily disassembled for cleaning. The conveyor belts themselves can also be easily assembled and disassembled. The machine is equipped with a pedal to change the two gears and a scale to regulate the thickness of the dough. High safety standards are guaranteed with two protective panels and a low voltage 24V electrical system in compliance with safety regulations. This machine is also equipped with two rolling pins, a flour sifter, and a flour collector under the conveyor belts. The belts can be lifted when the machine is not in operation to make the machine more compact. All of the sheeters are equipped with extractable belts.

Pull-Through Rack Dishwashing Machine

- Body and tank in stainless steel construction 18/10 AISI 304,

- Tunnel composition:

- Completely automatic

- Upper and lower fixed washing (60 °C)

- Upper and lower fixed rinsing (85-90 °C)

- Washing and rinsing arms in stainless steel constructions, easy disassembly, and interchangeable

- Double skin with thermic and acoustic insulation

- Slanted tank with rounded edges,

- Stainless steel auto draining washing pump,

- Counterbalanced door

- Front panel composition:

- Sequential visualization of inlet/washing/rinse water temperature

- Single visualization of the other temperatures through the push selector switch

- PCB-board programming according to the type of machine and the customer's demand

- Alerts and functions showed on a display

- Warning light indicating "door open “or absence of overflow (when present)

- Limit switch alarm

- Water-fail alarm (tank loading)

- Flux meter alarm (when present)

- Thermic relays alarm motors

- Signaling of various functions and cycles starting

- Rinse boiler filling daily starting

- Speed selection push button or machine running with a motor drive off

- Drying push button and light (when present)

- Pre-rinse push button and light (when present)

- Autotimer push button and light (when present)

- Rinse light

- Fluxmeter light (when present)

- Basket entry light (when present)

- Washing tank water level light

- Frontal maintenance

- Water protection

- Automatic tank loading

- Rinse economizer

- Tank and pump filters

- Insulated Boiler

- Overload cut-out indicator

- Frontal maintenance

- Water protection

- Automatic tank loading

- Thermometers for automatic control temperatures

- Rinse economizer

- Tank and pump filters

- Insulated Boiler

Reach in Refrigerator and Freezer

GN 1/2; (650 x 450) Reach in refrigerator GN 2/1 Series

Structure:

- AISI 430 stainless steel.

- Back of galvanized metal plate.

- 100mm diameter casters. Front casters with brake.

- Lift-up control panel for easy access to the condenser unit Lock.

- Wide rounded corners to aid cleaning.

- Drain inside the cabinet.

- Better energy class due to the optimized circulation of air, the use of R290 refrigerant, and electronic fans, for better temperature uniformity in the interior. 30 amp. control.

- Infrico is audited and certified by an international organization INTERTEK in accordance with UL 471 and NSF 7.

Record

Utility up-steaming, vacuum and air-blowing tables RECORD are the perfect combination of innovation and ease of use for top quality ironing and competitive prices. Record tables feature copious and well distributed steam from the board. Vacuum and air-blowing are powerful and constant; the air flow is adjustable and the optional "Energy Saver" device allows to save up to 30% steam thanks to instant steaming. Record is manufactured either self-contained, with 5lt (6 kW), 9lt (6 or 8 or 10 or 12 kW), 20 lt (10 or 12 kW) boiler, or for connection to central steam.

Record is available either with Maxi board or with Bottle-Neck (BN) board with the following board sizes:

- Maxi: dim. 1300 x 500 - small end 250 mm

- BN: dim. 1300 x 500 - small end 300 mm

- Twin heating elements (only for 20-lt boiler)

- Steam or steam/air spotting gun

- Water spray gun with support

- Arm with sleeve-ironing shape, topper shape or spotting shape

- Overhead gantry with or without pulley and iron suspension, with or without light

- "Small-end right operation" pack

- Instant steam device (ENERGY-SAVER version).

Refiner

This is the ideal machine for your pastry shop. It is provided with cast iron helical gears in a complete oil bath, grease nipples, and a modern system for fastening the scraping blades which make it extremely sturdy, reliable, and also very fast and easy to clean. Its robust structure includes a steel sheet base and cast-iron shoulders, making it an undisputed leader in the field of mixers. The perfectly faced porphyry cylinders may be separated from each other by a handwheel but still remain perfectly parallel. The rear cylinder turns on its axis for better refining. The machine is equipped with accident prevention features as well as a low voltage 24V electrical system in accordance with safety regulations.

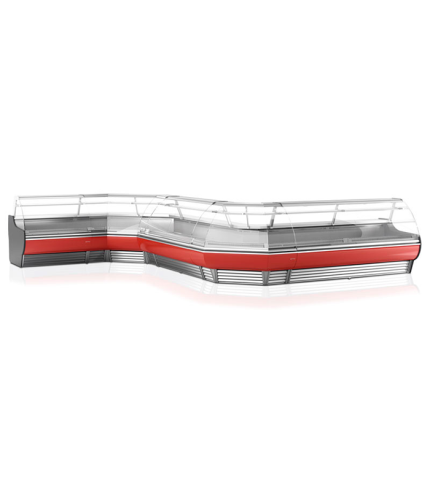

Refrigerated Modular Display Case

Madrid plug in counters are a range of cases with rear glass structure that include intermediate shelves with LED lighting to enhance the total visibility of the exposed product. Specially designed for the areas of sale of charcuterie, delicatessen and cheeses.

They offer an excellent implementation flexibility to put them where, how and when you want.

In its wide range of products you can find models with and without refrigerated reserves, all of them with a rear glass structure. You can also incorporate angles and neutral modules non-cooling. There are a wide range of options and accessories

Its wide exposure area of 810 mm and its intermediate shelf help expose the product to highlight its quality.

Modular line

Combination of different cooling system modules: ventilated, half static and static. Modules with or without cooled storage. Angles and counters to adapt the line to a space.

Leak detection system

All condenser units are tested 100%, in helium chambers to refrigerant leak detections.

Lighting

LED lighting incorporated, reducing energetic consumption between 80% and 90% respect to a traditional light bulb.

Certifications

Infrico is audited and certified by an international organization AENOR in ISO 9001: 2015 (Quality); ISO 14001: 2015 (Environment); OSHAS 18001: 2007 (Worker Safety and Health) and by INTERTEK in accordance with UL 471 and NSF 7.

Structure

Modular line designed for meat and precooked and packaged foods,

charcuterie, milk products and sandwiches.

Plastic coated steel exterior.

AISI 304 stainless steel worktop.

AISI 304 stainless steel exposure surface.

Lacquered DM decoration.

Folding secured curved glass.

Plastic coated steel interior.

Enamelled steel base.

LED lighted middle shelf and exposure surface.

Storage door clearance of 425×255 mm.

Refrigeration

Automatic defrost.

Ventilated condensation system.

Forced evaporation system.

Stainless steel evaporative tray with double vat, one for hot gas and another with electrical heater.

Refrigerated Modular Display Case

Madrid plug in counters are a range of cases with rear glass structure that include intermediate shelves with LED lighting to enhance the total visibility of the exposed product. Specially designed for the areas of sale of charcuterie, delicatessen and cheeses.

They offer an excellent implementation flexibility to put them where, how and when you want.

In its wide range of products you can find models with and without refrigerated reserves, all of them with a rear glass structure. You can also incorporate angles and neutral modules non-cooling. There are a wide range of options and accessories

Its wide exposure area of 810 mm and its intermediate shelf help expose the product to highlight its quality.

Retro-Wine Cellar

Design

Vintage wine cellars are manufactured for exhaling, maintaining and preserve wine, with a similar design to refrigeration equipment from the 1960’s decade, but designed with current manufacturing technology.

Structure

100 % solid pine wood.

5 shelves with wooden front per door, height adjustable and easily replaceable.

Lighting

LED lighting incorporated, reducing energetic consumption between 80% and 90% respect to a traditional light bulb.

Refrigeration

Temperature and automatic defrost regulated by a digital controller.

Evaporator treated with anti-corrosion polyester Epoxy.

Ventilated condensation system.

Ventilated evaporation system.

Retro-Wine Cellar

Design

Vintage wine cellars are manufactured for exhaling, maintaining and preserve wine, with a similar design to refrigeration equipment from the 1960’s decade, but designed with current manufacturing technology.

Structure

100 % solid pine wood.

5 shelves with wooden front per door, height adjustable and easily replaceable.

Lighting

LED lighting incorporated, reducing energetic consumption between 80% and 90% respect to a traditional light bulb.

Refrigeration

Temperature and automatic defrost regulated by a digital controller.

Evaporator treated with anti-corrosion polyester Epoxy.

Ventilated condensation system.

Ventilated evaporation system.

Salad Prep Refrigerator Undercounter

Energy efficiency

Improvement of the energy classification, due to the use of R-290 refrigerant, electronic fans and optimized circulation of the air for improved temperature uniformity in the interior.

New control system

The new user-friendly controller IP65 has greater precision in temperature control. Easier to adjust the temperature range we want to achieve.

Certifications

Infrico is audited and certified by an international organization AENOR in ISO 9001: 2015 (Quality); ISO 14001: 2015 (Environment); OSHAS 18001: 2007 (Worker Safety and Health) and by INTERTEK in

accordance with UL 471 and NSF 7.

Worktop EN (Salads)

Upper static refrigeration.

Important: The trays should contain previously refrigerated product.

New door design

New design of doors with double grip handle. Doors equipped with hinges for automatic return and permanent pressure during closing.

The automatic return is free when the opening exceeds 95º. They include four-chamber “clean less” flu at door gasket easily removable.

Refrigeration

Front-breathing ventilation system.

Evaporative tray without electrical heaters.

New Monoblock refrigeration system.